In mining, accounting for pre-existing discontinuities in fragmentation prediction has followed pragmatic empirical e.g. blastability approaches. Efforts to improve prediction and blast design are increasingly employing dynamic crack propagation models. Here, a discontinuous computational approach based on the combine finite-discrete element method (FEMDEM) coupled to a FEM multi-phase gas flow model is explored in the context of a blasting experiment for an unconfined rock block with various simple joint patterns. The discontinuity pattern of a rock block greatly affects the dominant mechanisms of fragmentation for the case of single hole blast and free boundaries.

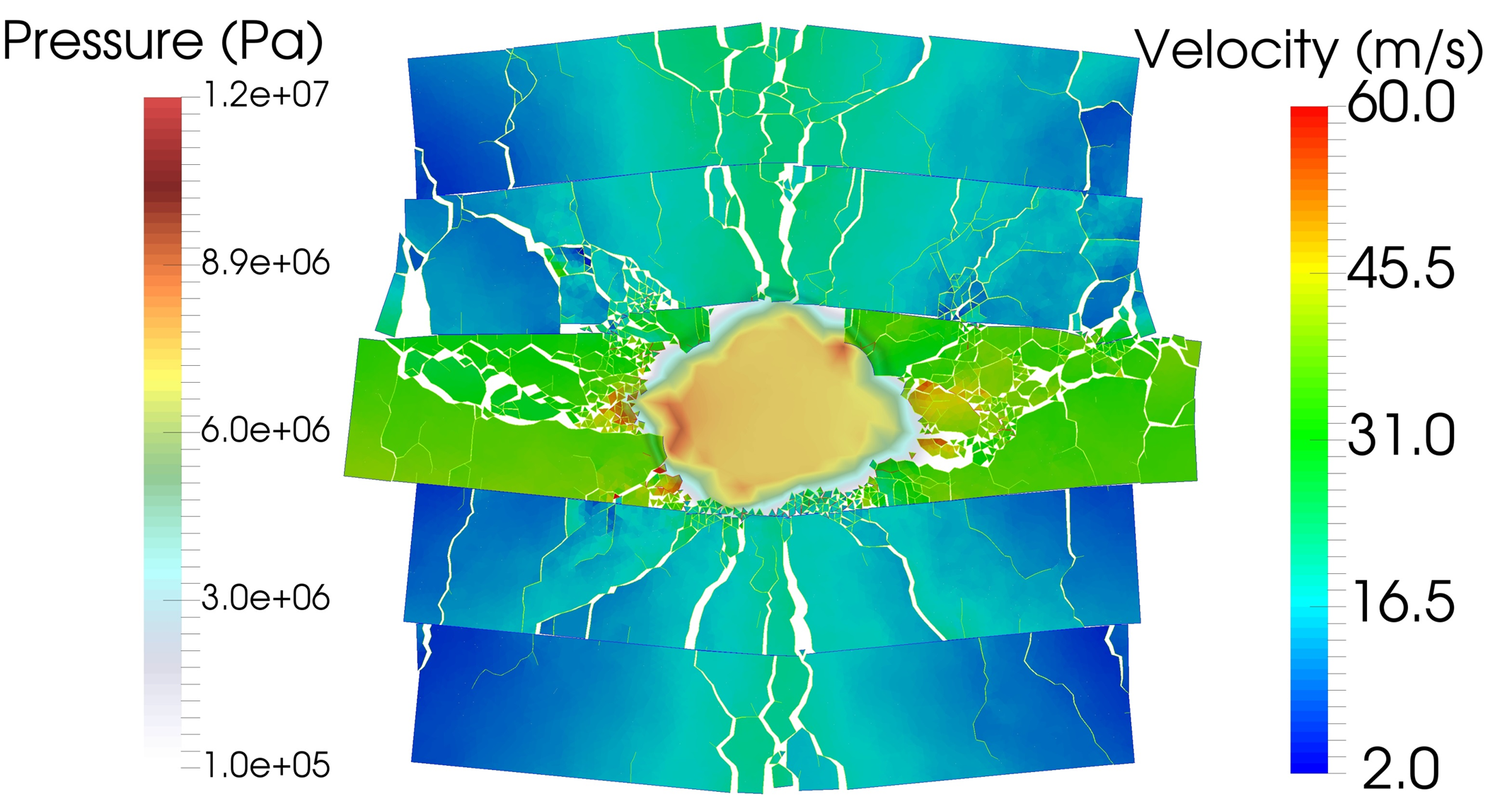

Below shows a high detonation pressure blast in a 1×1 m intact rock block with the pressure reduction and gas expansion shown by the change of colour scale. The pulverising granulation and shear fracturing is shown by red cracks while the tensile cracks, seen as radial and reflected wave slabbing cracks, are shown in blue. The lower right figure colour indicates velocity as fragments begin to fly (Yang et al. 2017).

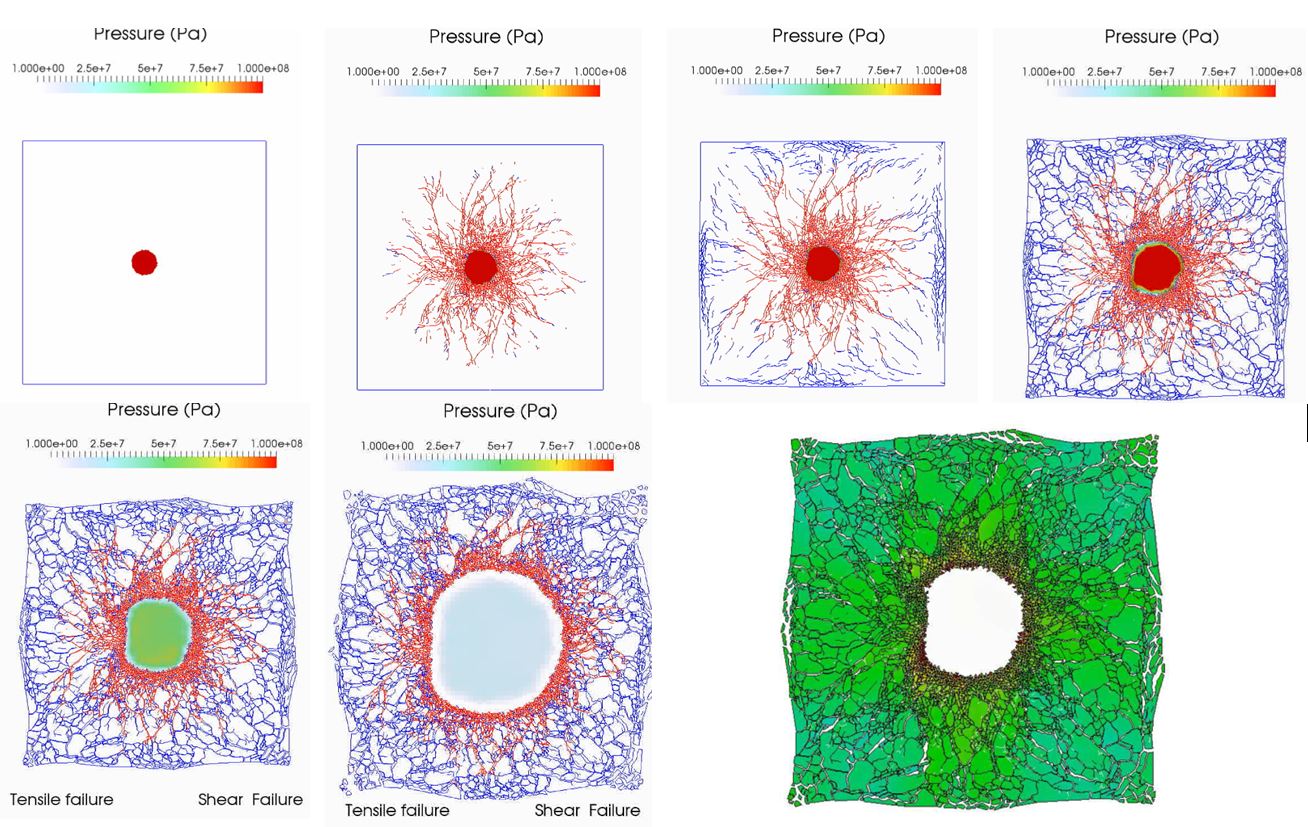

The following figures show blasting at a lower detonation pressure. The effect of pre-existing fracture planes can be seen. Here, the green fractures initiate in Mode 1 tension, while red indicates shear fracture initiation.

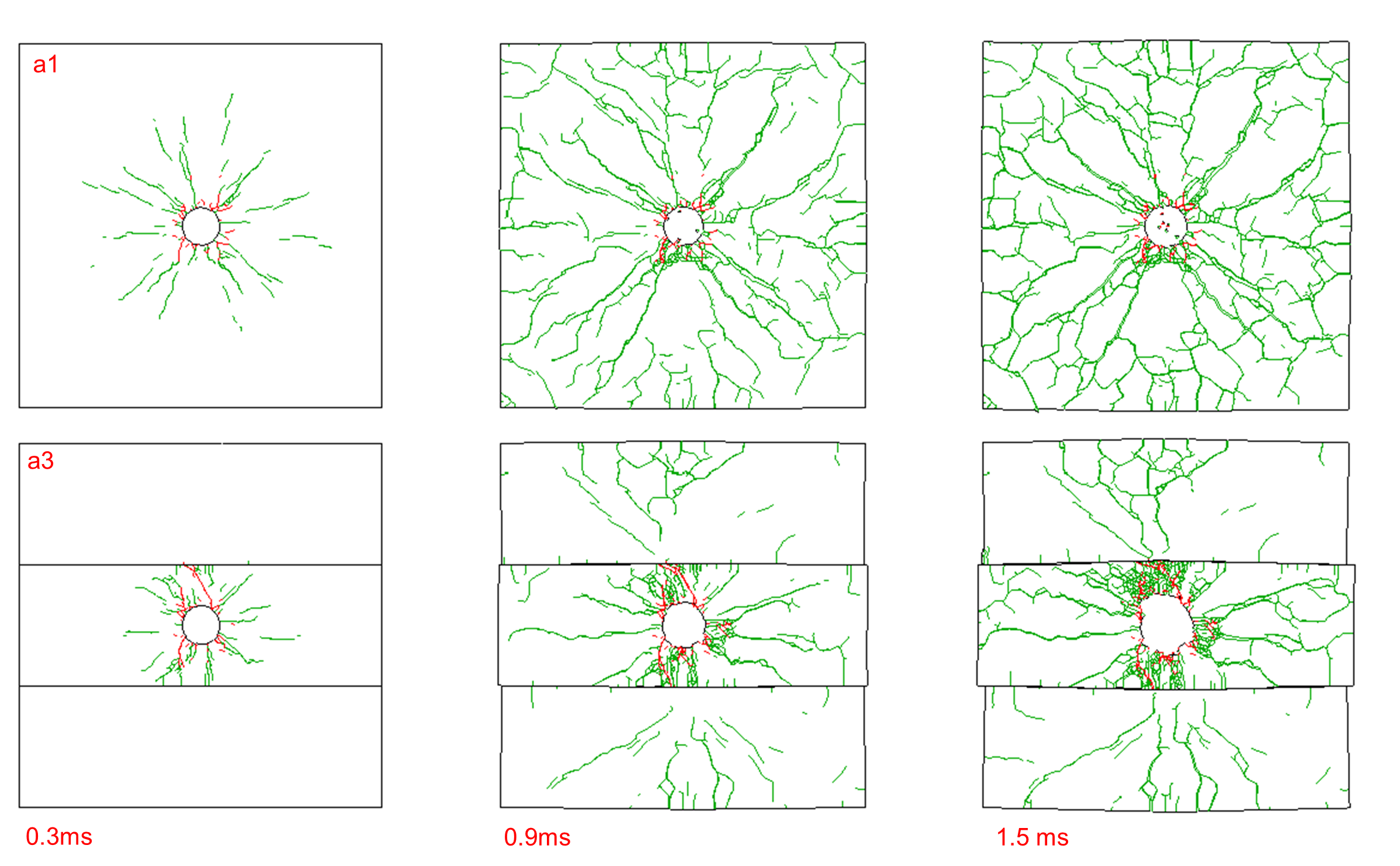

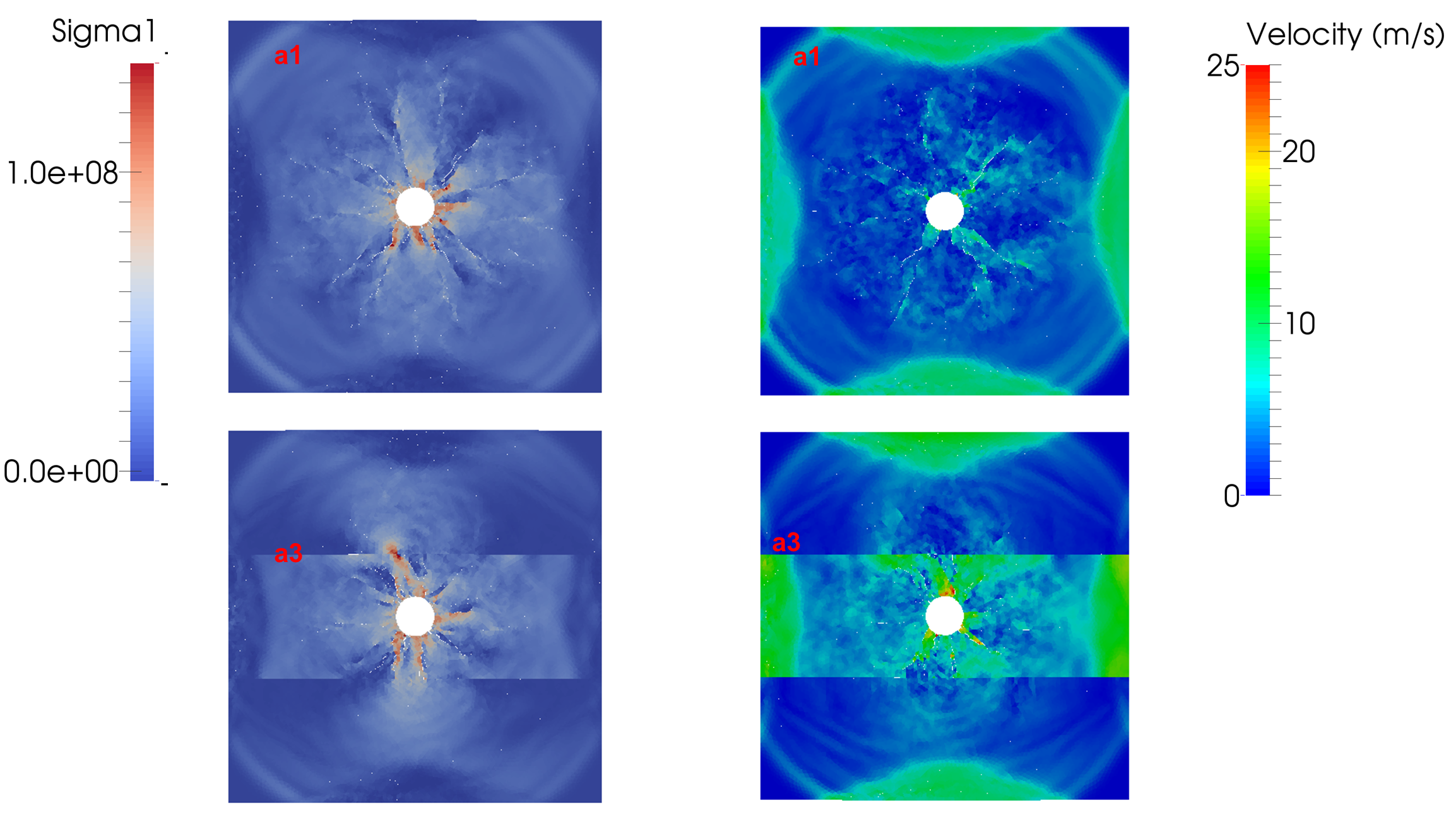

In the same two models shown below, the stress state and material velocity can be compared at an early stage 0.3ms after detonation

Another model with four pre-existing discontinuities is shown after 3.9ms. The fragmentation size distribution is discussed in the 2017 ARMA paper, (Latham et al. 2017).