This work is the collective effort of many researchers: Obeysekara, A., Latham., J.-P., Xiang, J., Lei Q., Salinas P., Pain, C., Yang P.

The FEMDEM model with fracturing and an empirical Joint Constitutive Model embedded in Solidity is fully coupled to fluids codes. Here, the coupled fluids code is a multiphase Darcy flow control volume finite element code. This enables the study of fluid driven, i.e. hydraulic fracturing or ‘fracking’ problems. Other geomechanical problems that can be tackled with this coupled formulation include the de-stressing and dewatering or degassing in tunnelling and mining operations and rock bursts, see also https://solidityproject.com/technology/fluid-structure-interaction-model/.

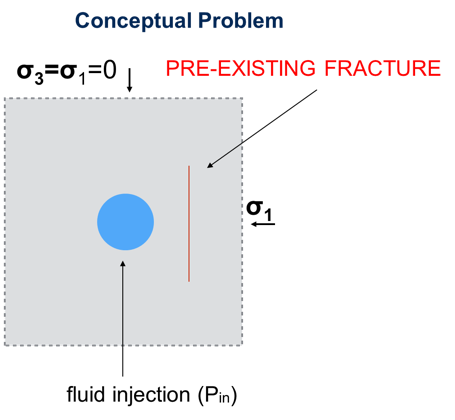

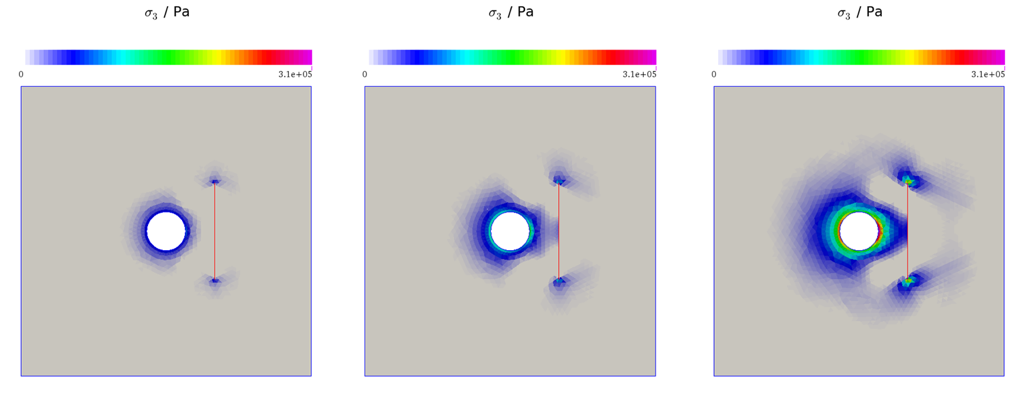

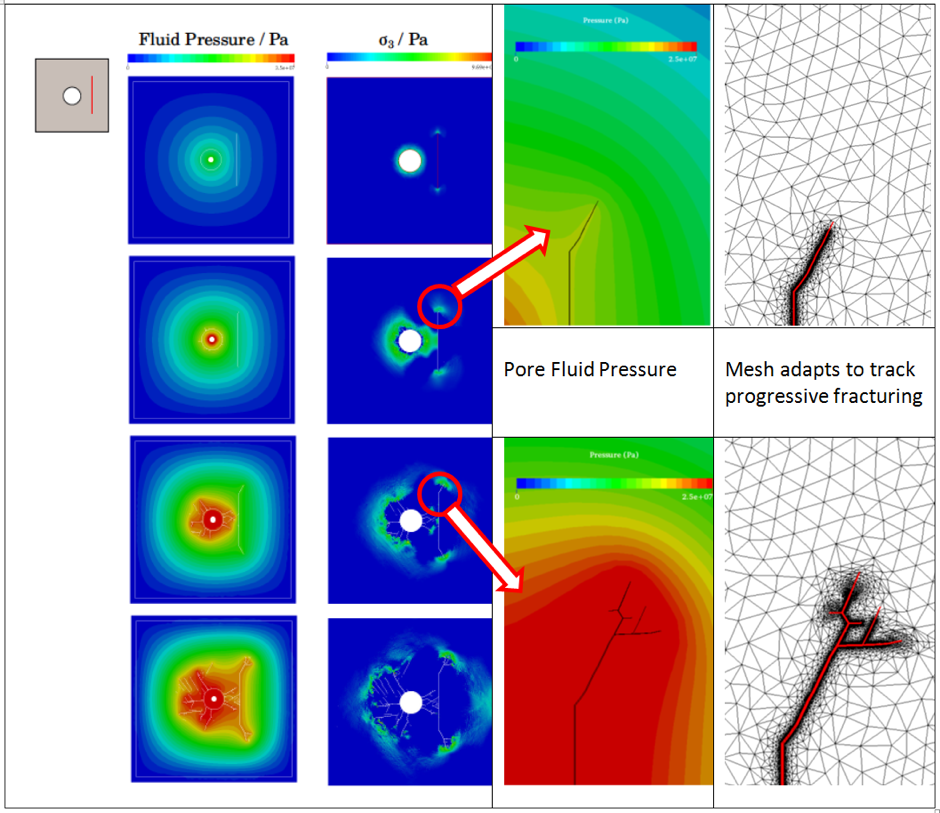

Below, the conceptual problem for hydro-fracking is shown greatly simplified. An in-situ (uniaxial in this case) boundary stress is shown and pore fluid is injected into a porous rock with a nearby pre-existing fracture perpendicular to the maximum principal stress. The snap shots after different times show the magnitude of the least principal stress growing significant tensile hoop stresses. With increasing pressure, the distortion of the concentric tensile stress is apparent due to the existence of the nearby fracture, tensile stresses being transferred to the crack tips. The simulation stops here at the point where radial cracks may soon break out from the well bore in addition to propagation from the old fracture tips, (see further deformation and cracking below).

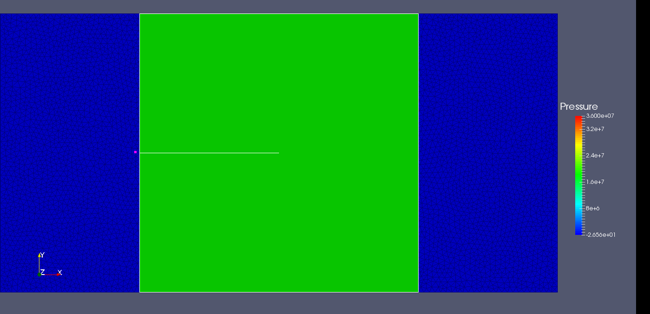

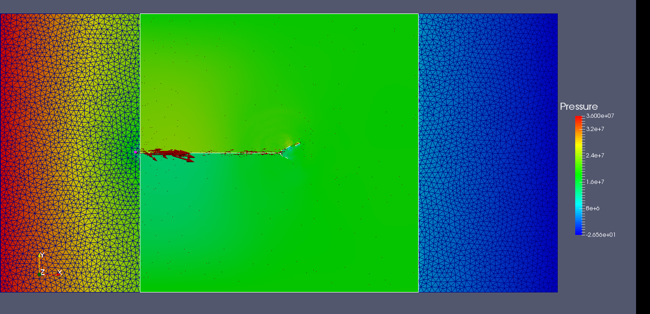

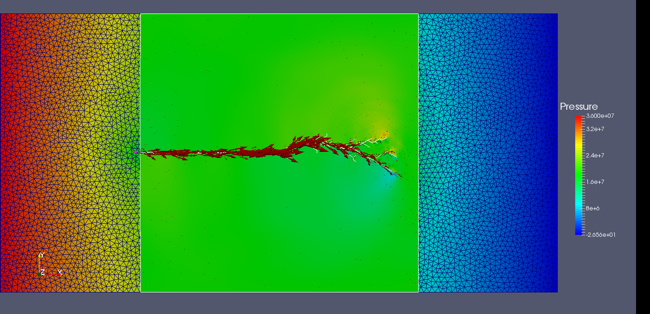

Fluid driven fracturing caused by applying a pressure gradient with fluid injection from left to right across a slightly porous rock with flow into a thin initial slot can be seen in the snap shots below. Note that in the solid, Darcy flow velocity is shown by glyphs and the colour change indicates deformation, as the hydro-fracture propagates. In the figure below, the porous media fluids mesh is shown fixed.

The adaptive meshing feature of the multiphase fluids code can be exploited to refine and coarsen as necessary. The mesh is shown here to refine down to the length scale e.g. ~50-100 microns, or as computed for the hydraulic aperture. Apertures for fracture flow are obtained from the geomechanical solutions for the pre-existing and growing new cracks obtained by the transient dynamic solver in Solidity. Fluid leak-off is captured automatically and artificial diffusion into the matrix is prevented by use of discontinuous galerkin methods (Su et al. 2015).

References

Obeysekara, A., Lei Q., Salinas P., Pavlidis, D., Latham., J.-P., Xiang, J. and Pain, C.C (2016). Fluid-Solid Coupled Approach for Numerical Modeling of Near-Wellbore Hydraulic Fracturing and Flow Dynamics with Adaptive Mesh Refinement. In 50th US Rock Mechanics / Geomechanics Symposium ARMA, Houston, Texas, USA, 26-29 June 2016.

Su, K., Latham, J.-P., Pavlidis, D., Xiang, J., Fang, F., Mostaghimi, P., Percival J.R., Pain, C.C. & Jackson, M. D. (2015). Multiphase flow simulation through porous media with explicitly resolved fractures. Geofluids 02/2015; DOI:10.1111/gfl.12129

Guo, L., Xiang, J., Latham, J-P., Vire, A., Pavlidis, D. & Pain, C.C. (2015). Numerical simulation of hydraulic fracturing using three-dimensional fracture model coupled with and adaptive mesh fluid model. In 49th US Rock Mechanics / Geomechanics Symposium ARMA San Francisco, 28 June-1 July 2015.

Latham, J.-P., Xiang, J., Belayneh, M., Nick, H. M., Tsang, C.-F., & Blunt, M. J. (2013). Modelling stress-dependent permeability in fractured rock including effects of propagating and bending fractures. International Journal of Rock Mechanics and Mining Sciences, 57: 100-112. doi:10.1016/j.ijrmms.2012.08.002