Background

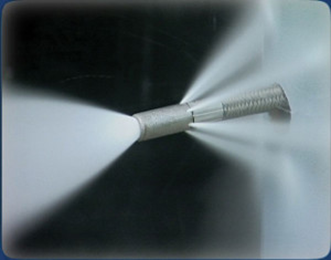

In our European research project on geothermal energy, (SURE) a most pressing challenge is being addressed: how to drill many lateral deviator holes to depth cheaply and control the fluid and thus the heat flow. Water jet drilling has become a very promising rapid and cheap technique in the softer rocks and is used widely in Oil and Gas. The aim of drilling technologists is to develop techniques to drill deeper into harder rock with water jetting. There are now some concerns that the small uncased holes created may degrade with time. Not all holes cut by the water jet are of circular section – this is because the jetting nozzle has forward facing (to erode rock) and backward facing jets (thrusters to propel the drilling forwards). The back thrusters leave behind a star shaped section hole. See figures below showing holes made in Berea sandstone, and please also visit the following link: http://staging.buckmanjetdrilling.com/wp-content/uploads/2017/06/BJD_drilled_Formations.jpg

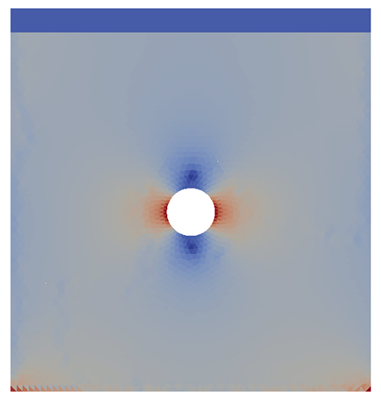

We have developed a code (www.Solidityproject.com) that can model the stresses in the wall rock and any crack development around the jetted holes, under stressed conditions. The response of a circular cross section to borehole breakouts is well understood.

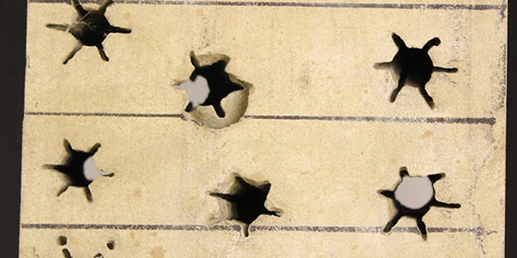

But for star-like shapes, no-one has investigated this shape effect on integrity of the hole in in-situ stress conditions. The project objectives are therefore very well posed and we have uniquely suited codes to investigate this with. For example, shown below are progressive crack propagation results in Solidity from internal rectangular holes under boundary loadings.

The Project

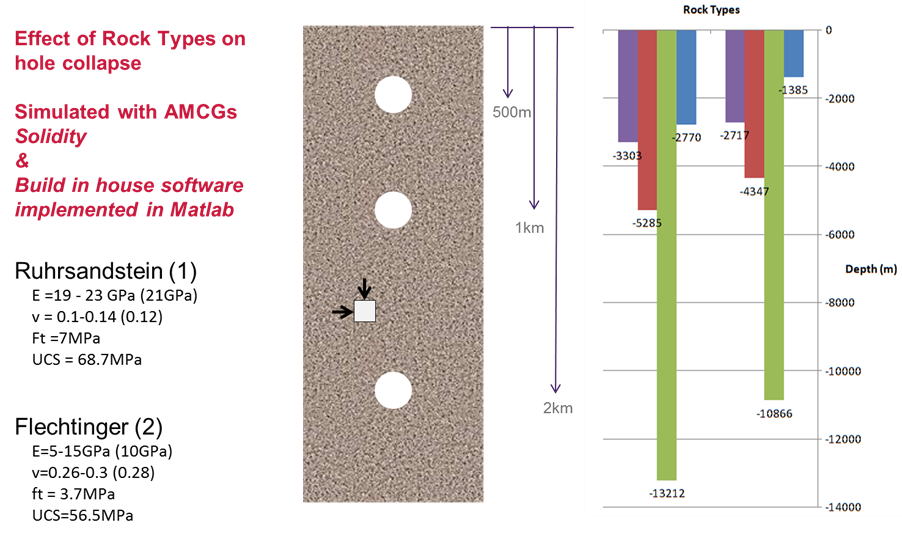

You will begin by checking that our software reproduces the analytic solution of the stress field around a circular opening (The Kirsch Equation solution) with in-situ boundary stresses representing different depths. We have made a start with this – see below.

Next, you will apply rock strength properties that will allow the rock to deform and fracture. When stress adjusts to the circular hole excavation – rock deforms inwards and may fracture in shear if the wall compressive stress exceeds the unconfined compressive strength, UCS. You will investigate the combination of conditions and rock strengths that result in fracture propagation and wall rock breakages. Taking data from images of jetted borehole profiles, seen above, a representative star cross-section will be created for the hole. The progressive failure path for the star cross section holes will be analysed. The in-situ stress causing initiation of failure in a star-shaped hole will be compared to a circular hole. A discussion will focus on proposals for a stability index that takes account of depth, strength measures and an assumed star shape. If there is time, the model will introduce rock microstructure or other forms of heterogeneity in the material strength of the rock.